Experienced professionals with a good understanding of the corporate environment

Experienced professionals with a good understanding of the corporate environment

INTRODUCTION

AddVantage Robotics & Automation Ltd. is engaged in the design, construction and modernization of custom manufacturing machines, components and devices. With the help of our engineers and specialists with many years of experience in multinational companies and outstanding competencies, we are able to find efficient and reliable solutions to the manufacturing technology challenges of almost any industry, with which we aim to increase the competitiveness of our customers. This is the key to the success of our company.

Experienced professionals with a good understanding of the corporate environment

Experienced professionals with a good understanding of the corporate environment

Flexible, efficient teams and agile project management

Flexible, efficient teams and agile project management  Precise process planning and execution

Precise process planning and execution

An organisation-wide drive to meet customer expectations

An organisation-wide drive to meet customer expectations OUR SERVICES

BESPOKE MANUFACTURING

Construction, rebuilding or modernization of production and control equipments and production lines

3D prototyping

Manufacturing and assembly of mechanical, electrical and electronic components

Manufacturing and surface treatment of individual or serial parts, experimental parts (based on own or existing designs)

MAINTENANCE

CONSULTANCY

DESIGN, PROGRAMMING

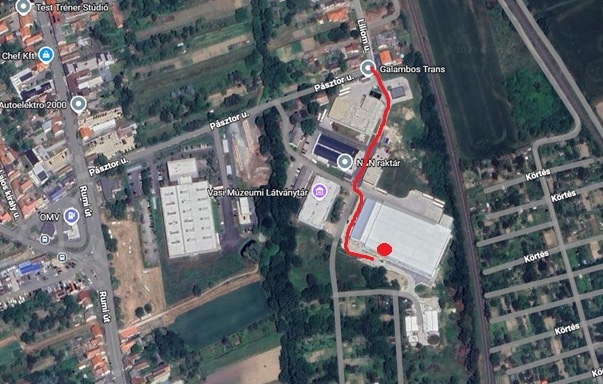

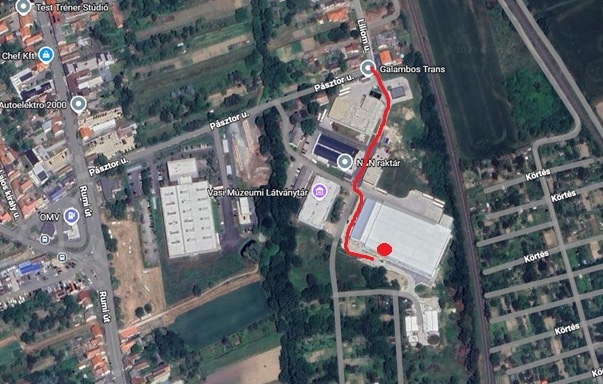

Contact

AddVantage Robotics & Automation Kft.

info@avra.hu

9700 Szombathely, Pásztor u. 2.

Help with directions:

Help with directions: